| Publication Details: | |

|---|---|

| Publication: | “PC Plus”, UK |

| Issue: | 81 |

| Date: | June 1993 |

‘PC PLUS’ BUYER’S GUIDE SPECIAL REPORT:

CAD SOFTWARE

In Industry’s fight for survival, Computer-Aided Design software has become a vital weapon for companies of all shapes and sizes. But what is it, and how do you choose the best system for your needs? TIM BATY takes a peep over the parapet…

Computer-Aided Design (CAD) software, once the preserve of the Aerospace and Motor industries, is rapidly becoming accepted as one of the ‘top 5’ PC applications after Word-Processors, Spreadsheets, Databases and Desk-Top Publishing systems. Prices have dropped from the hugely expensive Mainframe and Mini-based pricing structures prevalent in the 1970s, to street prices of £80 or less for a basic drawing program today.

So what exactly is CAD? CAD programs are distinguished from other drawing and painting programs by the way in which they store data. A painting program, such as Microsoft Windows Paint, stores a picture like a sheet of graph paper with squares filled in. Although what’s stored might look like lines and circles, the image is actually made up of a series of points, or pixels. A CAD program, on the other hand, stores the features in a drawing as geometrical objects such as ‘lines’, ‘circles’ and so on. The benefits of this are firstly that the exact location and size of the objects on the drawing can be stored to high levels of accuracy, and secondly when you magnify a detail the accuracy is preserved – the image doesn’t break up into blocks. CAD programs also make few concessions to beauty, being geared towards the clear and accurate presentation of technical information, rather than creating sophisticated works of art.

Although many people think of CAD as being primarily concerned with the creation of 2-dimensional drawings, in fact its abilities go way beyond this. Programs are available which are appropriate for each or all stages of the design and development cycle, from the first simple sketches of a concept, through design, modelling and simulation of behaviour, to final detailing and the preparation of drawings for manufacture. The natural candidate for a CAD program is someone who designs and draws for a living, such as a draughtsperson, architect, or industrial designer. However, the introduction of low-cost, easy-to-use programs such as AutoSketch has brought CAD facilities within the reach of people who only occasionally need to create simple technical drawings. Customers for this type of program might include home users, sales & marketing staff, and technical authors.

The CAD market is unusual in that, in addition to general-purpose design and draughting programs, which attempt to be all things to all people, there are a large number of products which cater for particular industry sectors, or more specialised types of design task. Some of these products are utilities which work in conjunction with a general-purpose program: AutoCAD is particularly well provided for here, with nearly 500 authorised add-ons available. Other products are complete, independent CAD programs, designed from the ground up to take account of the special needs of a particular design task. Activities catered for in this way include Mechanical Engineering & Draughting, Building Design, Industrial Design and Product Styling, Electronics Design and Printed Circuit Board Layout, and Facilities Planning and Building Management.

When potential customers first start to look at CAD programs, it’s common to be completely overwhelmed by the sheer number of facilities even in low-priced programs. Thankfully, all programs’ features can be broken into just a few major sub-groups. The first group concerns the business of actually creating the drawing. All CAD drawings are built up from simple geometrical shapes, known as entities or primitives, such as lines, circles, arcs, text and dimensions. Some programs store the data using different kinds of entity, so for instance the primitives in a 3D program might include spheres, cones, cubes and so on, but the principle is essentially the same.

Once a drawing has been started, changes will inevitably be needed, so the second group of features involves tools for manipulating the contents of the drawing. Commands to move, copy, rotate, mirror, scale or erase existing entities are typical examples. It’s important to remember that because a CAD system stores a drawing as a collection of lines, circles and so on it’s easy to pick out particular entities for modification. Consequently, most programs will have various methods of selecting features either individually or by placing a ‘window’ around them.

The next category of features concerns what the user actually sees on screen. Because of a CAD program’s inherent accuracy, it’s possible to magnify a section of the drawing to work on fine details in close-up. Consequently, most programs have a good selection of commands to enlarge or reduce areas of the drawing, or ‘Pan’ across to other sections. Some programs allow the user to set up multiple windows on the screen, allowing the simultaneous display of different sections of the same drawing. A different method of controlling what the user sees on screen involves the concept of Layers. Layers are rather like a series of transparent overlays that contain the various entities and can be switched on or off at will. A simple example in architectural work would be to place all the ground floor’s features on one layer, the first floor on another, and the roof on a third. The ground and first floor layers could be switched off, permitting modifications to the roof without affecting the other details.

In common with other PC applications, CAD programs contain facilities to generate prints and plots, and to save and retrieve work on disk. Where CAD departs from the norm somewhat is that it always contains tools for grouping primitives together to form complex single entities known as blocks or shapes. Blocks represent one of the most useful of all basic CAD features, allowing users to create libraries of commonly-used details and re-use them in future drawings. Using an example in architecture again, it would be possible to store standard windows and doors as blocks, and add them to new drawings with the minimum of effort.

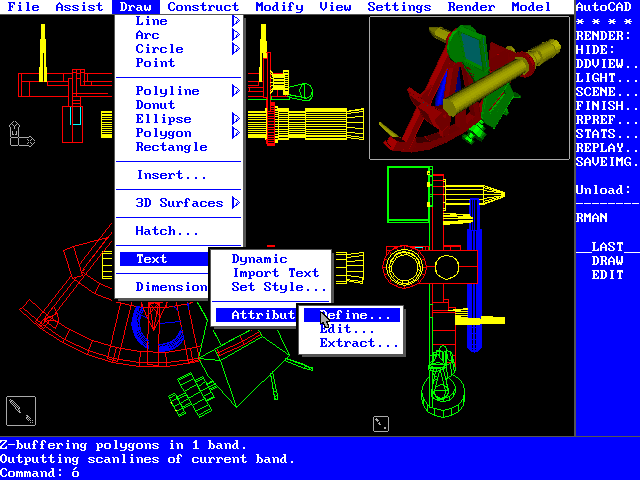

All CAD programs have features which fall into the categories described in the previous sections, although the exact range of facilities depends upon the program’s intended function. Many first-time buyers of CAD look at general-purpose programs, and once again it’s easier to analyse these products by dividing them into just a few program families. The commonest types of CAD program by far at the budget end of the market are those used for 2D Draughting. These programs, typified by AutoSketch and TurboCAD, allow the user to draw on a flat plane in a similar manner to a conventional drawing-board. One step up from 2D Draughting is 3D Surface Modelling, which provides basic features for drawing in 3 dimensions. Surface Modelling can simply give 2D features thickness by ‘extruding’ them, or can provide more realism by allowing the creation of planes anywhere in 3D space. Because of the similarities between 2D entities and 3D surfaces, many such 3D programs will also have excellent 2D Draughting facilities. AutoCAD and Microstation are the two front-runners in this group. Although much can be achieved with 3D Surface Modellers, certain kinds of work, particularly Mechanical Engineering and Product Design, need an understanding of which side of a surface is solid and which side is fresh air. 3D Solid Modellers achieve this by using drawing entities which are true solids, such as spheres, cones, cubes and cylinders. A well-known example of this type of program is 3D Studio.

Beyond the basic types of general-purpose CAD programs, there are many products which cater for particular industry needs. Many of these products work by taking data from the CAD program and feeding it into a different type of computer system, perhaps in another department. For example, linking a CAD system to a database or stock control system can allow it to create Bills of Materials automatically, which can be of enormous benefit in both engineering and architectural work. Another use of databases linked to the CAD system is Drawing Office Management, controlling modification and access to drawings (this can be a serious issue in a busy office with perhaps 5,000 CAD drawings in their network’s fileserver). In engineering, direct use can be made of drawing information. Sending CAD data into a Numerically-Controlled milling machine or sheet-metal cutter means that the data does not have to be manually keyed into the machine, giving significant improvements in quality and speed of manufacture. An extension of this is to use Stereo-Lithography to create prototypes of complex parts straight from a 3D CAD model. Moving away somewhat from pure engineering, many Product Designers and Stylists rely on the ability of their CAD systems to create realistic images of new designs before going to the expense of making prototypes. Other programs provide features such as the preservation of electrical connections between a Circuit-Diagram for an electronics design and its equivalent Printed Circuit Board.

At this point it’s useful to consider how much impact CAD’s introduction can make to the design and manufacturing process. For many first-time buyers, the justification for purchasing CAD software comes through the wish to speed up the creation of drawings – put simply, the goal is to create the same type of paper drawings, but a lot faster and more neatly. However, although a valid reason for buying a CAD system, this perception of the system’s function severely restricts the potential improvements in productivity. While productivity gains of 70% are possible for the task of creating and modifying drawings, this represents an improvement in only one activity. Further gains can only be achieved by looking beyond drawing generation, and allowing other departments or individuals to ‘borrow’ the data in the CAD system for other purposes. Enormous overall increases in speed, quality and efficiency can be gained by following this route.

But just how much will this productivity cost? CAD programs fall into four broad bands, depending on the facilities on offer. At the budget end of the market, basic 2D Draughting programs such as AutoSketch or TurboCAD are available for between £50 and £150. While these programs have some restrictions and are strictly 2D, they are still suitable for a surprisingly wide range of routine drawing tasks. The next price-band is around £400-£500 for the likes of Generic CADD or Drafix. These programs contain a great many more features, although usually still restricted to 2D Draughting. Additional software modules are available for some programs to cater for 3D. Used with care, programs at this level can begin to cope with full-time drawing duties in less demanding environments. Moving up to professional packages such as AutoCAD or Microstation represents a big jump in costs, with most programs falling in the £2,000 to £3,000 band. These programs are generally capable of both 2D and 3D work, and tend to be crammed with features to permit their use in almost all industry sectors. It’s important to remember with general-purpose programs at this level that there may well be considerable additional expenditure involved, either in purchasing add-on software modules for industry-specific tasks, or in developing custom features in-house. It might be more economical in some cases to look beyond a general-purpose program towards something more specialised. However, prices for industry-specific software can be frightening. For instance, Racal’s popular CADStar program for Electronics Design and Printed Circuit Board Layout will leave little change from £8,500 for its maximum specification.

A significant feature of the PC-based CAD market is that it is dominated by one program: AutoCAD. Since its launch in late 1982 it has sold more than 650,000 copies worldwide and over 50,000 in the UK, and has helped to change the CAD market from a specialised niche to a major business application. Today there are more AutoCAD seats internationally than all other professional PC CAD programs put together: industry surveys by Daratech suggest that AutoCAD accounts for 72% of all seats at this end of the market. This is, of course, not necessarily a bad thing. The enormous popularity of the IBM PC and its clones changed ordinary users’ perceptions of computers for ever, and useful comparisons can be drawn with what AutoCAD has done for the PC CAD market. It has encouraged open CAD software architectures, allowing users and developers to add features or customise the program easily. Its success has meant that the product available today is reliable and well-proven, and has raised confidence in the viability of such products in professional applications. Finally, AutoCAD’s DXF drawing data interchange format has become a de-facto standard for transferring CAD data at all price-levels from budget drawing programs to UNIX workstations, helping to break down the barriers between different manufacturers’ systems.

While CAD can undoubtedly transform drawing speed, some factors need careful consideration before installation. Firstly, mid-priced and professional CAD programs involve a great deal of commitment in order to extract the maximum benefits. This goes well beyond the initial purchase-price of the program and hardware. For instance, the sheer complexity of professional packages demands considerable funds and time for formal training. A training-period of two weeks per operator to achieve basic competence is not uncommon at this price-level. After the formal classroom-bound training period, further allowances should be made for new users to build up speed, with most people taking about three or four months to get close to their maximum. Consideration should also be given to poor system reliability in the first few weeks after installation. CAD is one of the most demanding applications for PCs, and when combined with the routine use of relatively unusual hardware such as high-quality graphics cards, or running the programs on networks, problems are inevitable. It’s important to allow plenty of time in the first few weeks to thoroughly debug all problems as they occur. Finally, don’t forget to establish in-house conventions for system use, and to start building symbol libraries.

While the user can usually tackle the points raised in the previous paragraph, a high level of commitment will also be required of management at director level if the system is to be of maximum benefit. The single most important factor here is that the company’s directors must be enthusiastic and eager to become involved with CAD – such a project is never entirely successful if the pressure to introduce CAD comes from below. Secondly, senior management should try to develop an awareness of the CAD system’s potential, and what can be realistically achieved. When a system is first introduced, it’s normal to progress towards maximum productivity in small, manageable steps, rather than trying to start from scratch with an all-embracing solution. In the early days it’s important both to have an open mind about which areas offer scope for further automation, and to find out which CAD avenues are being pursued by other companies. Senior management is also needed to ensure the co-operation of departments, particularly where the CAD system’s data will be shared with other departments. It is inevitable in such cases that the operational needs and procedures of those departments will be affected far more than they initially appreciate, and this can sometimes lead to a certain amount of resistance to the CAD system. In these circumstances the directors may well be obliged to insist on co-operation.

A final factor which senior management should consider is the need to provide a long-term CAD budget beyond the initial purchase of the system. While this is a particularly bitter pill for financial directors and accountants to swallow, it’s important to remember that every CAD program is subject to improvements which can have a dramatic effect on user productivity, and that these enhancements should be exploited at every opportunity. The rate of change here seems to be about twelve to eighteen months per major upgrade, with typical upgrade costs of ten to fifteen percent of original purchase price. When discussing long-term budgets, provision should be made for frequent replacement of the hardware on which the CAD program runs. Employing the fastest CAD hardware always shows clear productivity gains, but has the unfortunate effect of accelerating the rate at which hardware becomes obsolete. Experience has shown that CAD hardware is often effectively scrap after only three years.

CAD programs are now available at all price-levels, encompassing facilities from simple 2D Draughting through to 3D Solid Modellers. Chosen carefully and used with enthusiasm, they offer huge potential gains in productivity, but only if users go beyond merely using CAD to create paper drawings more quickly and exploit direct links with other departments’ computer systems. Higher level CAD programs demand a long-term commitment from everyone, both users and senior management alike, if productivity is to be maximised. The use of CAD technology is today becoming commonplace in all types of industry, and in companies of all sizes. Some industry sectors are already at the point where companies who have not yet invested in CAD are at a serious disadvantage, particularly when existing CAD users are always exploring ways to enhance their systems’ usefulness. However, the costs of investing in CAD software are potentially high, and there are many examples of companies who fall into the trap of choosing a system which is too expensive and too sophisticated for their actual needs. With budget CAD programs costing as little as £100, it may be more prudent to buy a simple program just to learn which features are genuinely important to your work.

Tim Baty

CAD SOFTWARE FEATURES CHECKLIST

ACCURACY

Some programs sacrifice accuracy for speed. This can cause problems when creating fine detail in large drawings, so go for the highest precision you can.

HARD LIMITS

Make sure that there are no ‘brick-wall’ limits on drawing complexity, such as the size of drawing-file being limited by available memory.

DATA EXCHANGE

The ability to exchange data with other systems is absolutely vital. Drawing eXchange Format (DXF) is common on PCs, while Initial Graphics Exchange Standard (IGES) is more normal on mainframe systems. Go for systems with both if possible.

SYMBOL LIBRARIES

Make sure that you can group features into symbols, and save them to disk to create libraries.

LAYERS

Drawing features on different Layers allows you to make them invisible while you edit neighbouring items – a godsend in a complex drawing. Look for as many layers as possible.

VIEW CONTROL

You’ll need to edit details frequently, so check you can easily Zoom in and out, Pan and create Multiple Windows. Camera position controls, and surface shading or rendering are also important in 3D packages.

EDITING TOOLS

Choice is vital when editing. Consider as the bare minimum Move, Copy, Rotate, Scale, Stretch, Mirror and Array.

DIMENSIONING

Dimensioning a drawing is one of the most commonly-performed operations of all. Look for plenty of Linear, Radius, Diameter and Tolerancing dimensioning tools. A useful time-saver is Associativity between the distance and the dimension’s text, where the text is re-calculated as the distance is changed.

HARDWARE

Video presents the greatest selection problems. A fast SVGA card is the safest bet, but check that higher resolutions are supported. For hard copy, Hewlett-Packard plotter, and Epson and Laserjet printer drivers are almost universal. Tablets are faster than screen menus for command selection – many can emulate Summagraphics’ Summasketch or MM1201 series.

Electronics Design Automation (EDA)

CAD software has been popular for years in electronics circuit design and simulation, and Printed Circuit Board (PCB) layout. It’s a highly specialised application, with several features which are quite different from those of general-purpose CAD programs.

Most EDA CAD systems contain three programs, for drawing circuits, laying out PCBs, and defining components. An important feature is the ability to maintain electrical connections and component references between circuit diagrams and PCBs. A circuit diagram’s features are translated into a text-file (the Net-List) which tells the PCB layout program what’s in the design, and how it’s connected together.

Some systems can simulate a design’s electrical behaviour entirely in the CAD program. Many look at the interconnections, and calculate the components’ optimum positions on the circuit-board (Auto-Placement) and the interconnections’ most efficient route across the board (Auto-Routing).

It’s worth remembering that many electronics designs today would be impossible without CAD. For example, many of the PCBs in the average computer contain so many interconnections and components that they would be uneconomic to lay out using manual techniques. When such productivity is combined with excellent reliability and modest costs, the huge popularity of EDA programs in electronics design becomes understandable.

TEN ESSENTIAL QUESTIONS TO ASK BEFORE BUYING

1. HOW MUCH WILL IT BE USED?

It’s important to strike the right balance between richness of features and ease of use. Complex professional systems will be totally unsuitable for occasional use, extensive training being needed to exploit them fully. Similarly, simple budget-priced drawing programs seldom have the overall speed or features needed for full-time work.

2. HOW SPECIALISED ARE MY NEEDS?

Resist the temptation to go straight for a highly-specialised program if your organisation doesn’t have CAD in any form, because you almost certainly won’t have predicted all its potential uses. A general-purpose program with good customising features is often more successful as a first step, as it can be adapted when your uses become clearer. Industry-specific CAD programs are only suitable if you are confident that your needs match their facilities exactly.

3. HOW AMBITIOUS ARE MY GOALS?

If you intend to place CAD at the heart of your company’s operations, you should look for plenty of facilities for communicating with the outside world, particularly database links and neutral file-formats such as DXF or IGES. Check also for third-party add-ons – these may handle the links you need already. Don’t forget the option of having bespoke software written for you, although this can be hugely expensive.

4. HAVE I PLANNED HOW TO INTRODUCE CAD?

Above all, get senior management on your side. Ensure that you have strategies for staying up-to-date, organising training, establishing the system, and getting other departments’ co-operation.

5. DO I NEED TO EXCHANGE DATA WITH EVERYONE ELSE?

You might think you want CAD just to produce paper drawings, but sooner or later you’ll need to share CAD data with other systems, usually through DXF or IGES. Even if you don’t swap drawings, hooks to non-CAD programs like databases are always useful. Make sure also that the program works properly on a network. Of course, the cynical solution to data exchange is simply to buy the same CAD program as everyone else (in most cases AutoCAD)…

6. CAN IT COPE WITH UNEXPECTED FUTURE NEEDS?

Uses of CAD can never be predicted accurately, so don’t set your sights too low in terms of program features. CAD programs usually end up being put to more uses than anticipated, so consider links beyond your department, customisability and availability of add-on products.

7. CAN I USE A DRAWING I DO TODAY IN FIVE YEARS’ TIME?

When users buy CAD systems, they actually buy the means of creating a library of drawings, many of which will be used actively over many years. To avoid problems, look for a good record of long-term product support, popularity, and the supplier’s guarantee that all future versions of the program will be upwards-compatible with the version you buy.

8. HOW GOOD IS AFTER-SALES SUPPORT?

CAD software always needs more support than other programs, so make sure that your choice has plenty of sensibly-priced training courses, good technical support both for bug-fixes and simple advice, and large numbers of third-party add-ons to cater for future needs.

9. WHAT PLATFORM WILL IT RUN ON?

Make sure that the host PC has the necessary horsepower – at all price levels, speed & fast throughput really help. CAD programs stress all parts of a PC, both in terms of speed and storage. Some programs have very specific and demanding hardware requirements, so check that the chosen program will run on your PC. If in doubt, buy the program and the machine as a package from a reputable dealer. Don’t forget that some popular CAD programs do not run under Windows, which may give problems in corporate environments.

10. HOW GOOD IS THE USER INTERFACE?

Assessing the look and feel of a program is highly subjective, and User Interface design problems may not become apparent until long after installation. However, two points stand out in terms of avoiding long-term difficulties. Firstly, look for a program which offers a choice of ways to drive it – for instance, allowing the user to swap at will from the keyboard to the Tablet menu to the screen menu. Secondly, find out if it’s possible to modify the user interface to suit your own requirements.